HILLCREST & WAHTOKE #57

The #57 was the first locomotive completely designed and built by the Hillcrest & Wahtoke Railroad Shops (later renamed Hillcrest Shops). It was out of sheer need for a workhorse to help build the first major expansion of the railroad.

Hauling the work crew in for dinner.

Ballasting the new track.

All of the drip irrigation in the new area was laid using the #57.

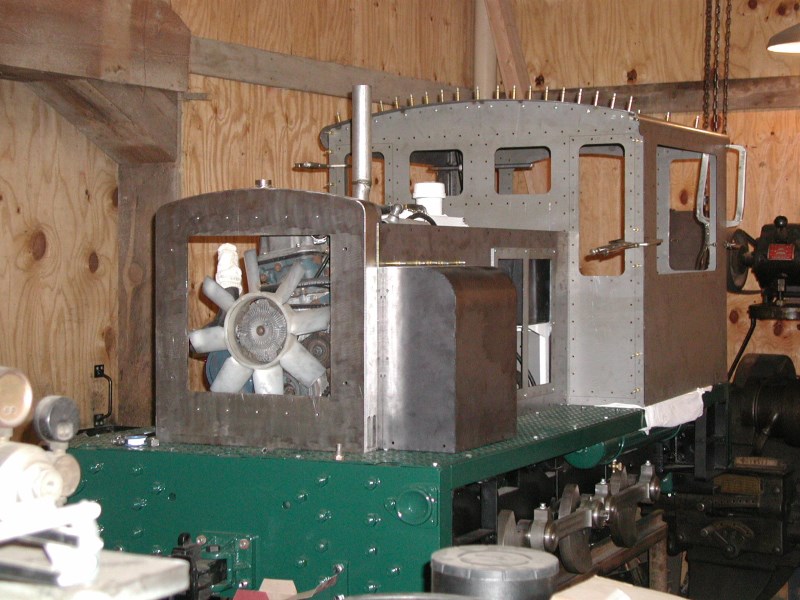

And this is where is all started.

An LGB model. There is an existing similar prototype in Colorado, however, it's only an 0-4-0 version.

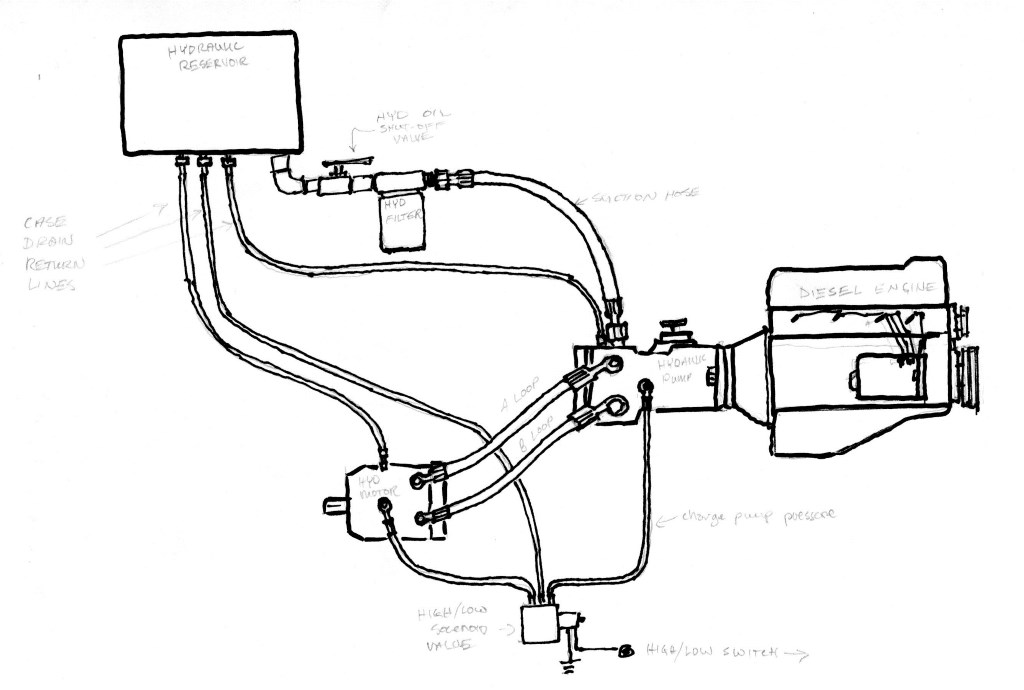

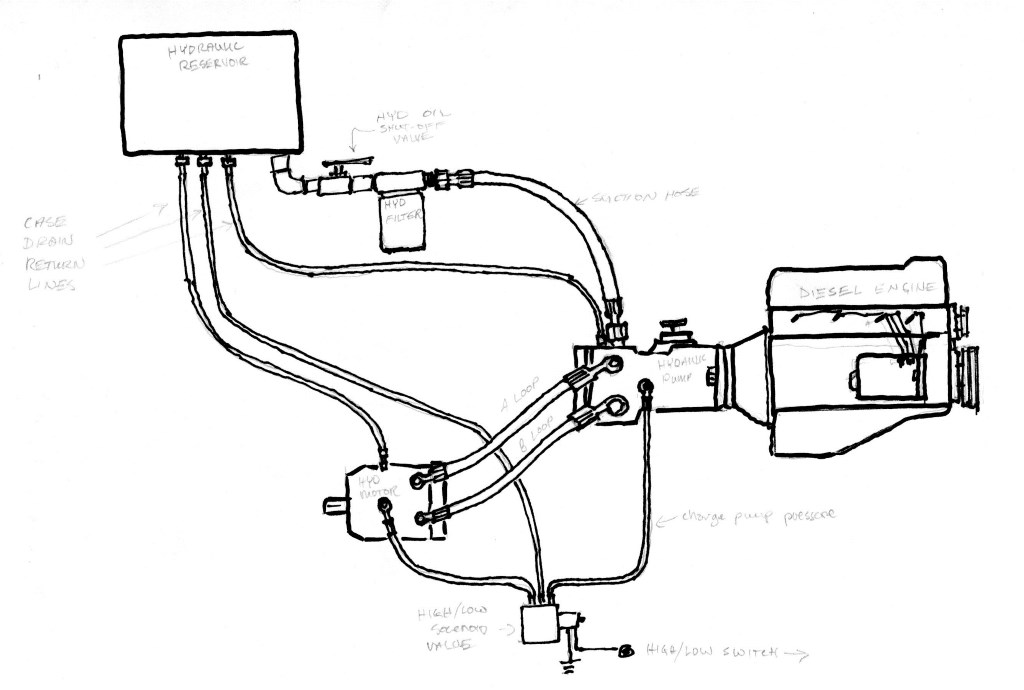

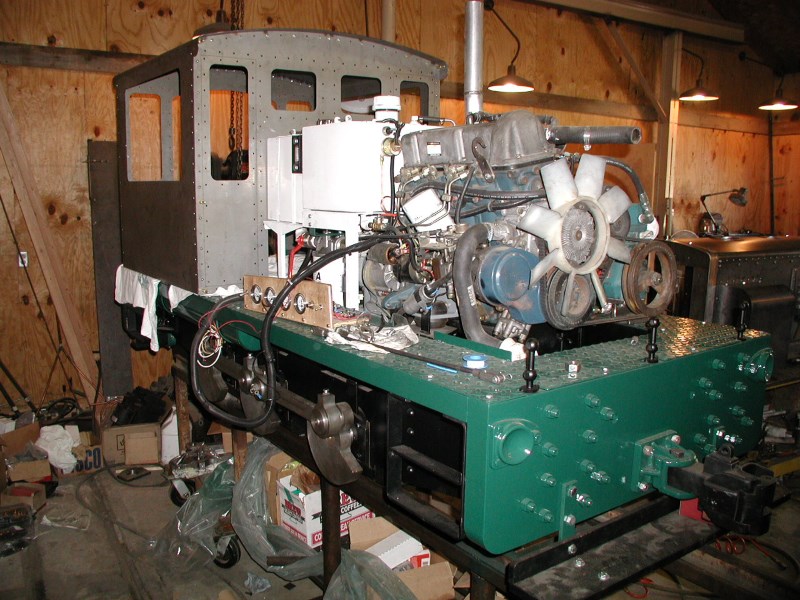

The decision was made early on to make it a Diesel-Hydraulic powered locomotive. This would allow for flexibility in the drive system to fit the small outline of the hood, along with providing copious amounts of power and very fine control.

The frames were cut from solid slabs of steel plate. Unlike planes or automobiles, locomotives need to be heavy. The more weight a locomotive has, the more work it can do, thus our Davenports are built with industrial grade and very thick structural steel parts. Weighing in at just over 5,500 lbs. the #57 among the heaviest 15" gauge locomotives in the USA, and it's 1,400 pounds of Tractive Effort / Draw Bar pull ranks it among the most powerful as well.

Likewise the Drive Wheels too were cut from rounds torch cut from 3" thick steel plate.

Drive wheels assembled including gearbox. One of our mantras in building this engine was "NO CHAIN DRIVE". We wanted it to be bulletproof and powerful. Chain drive would have been cheaper, but, it would have been cheaper.

The frame going together.

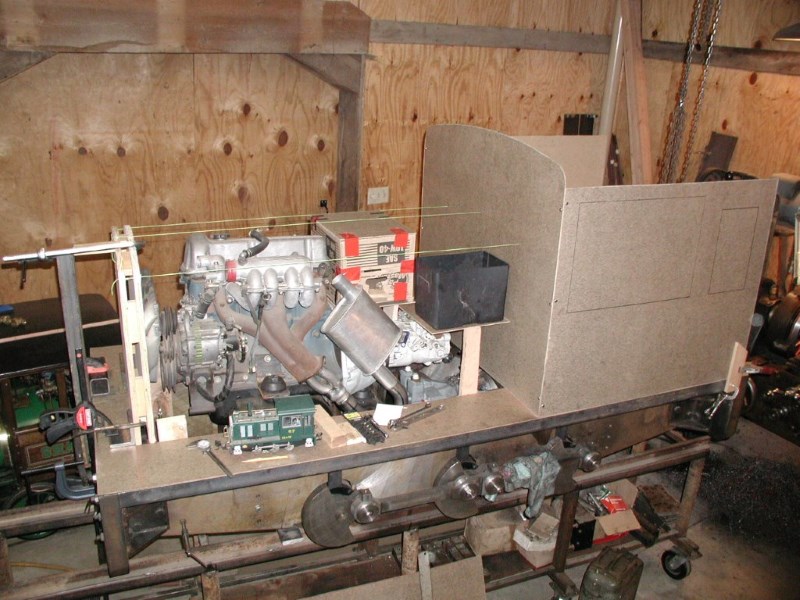

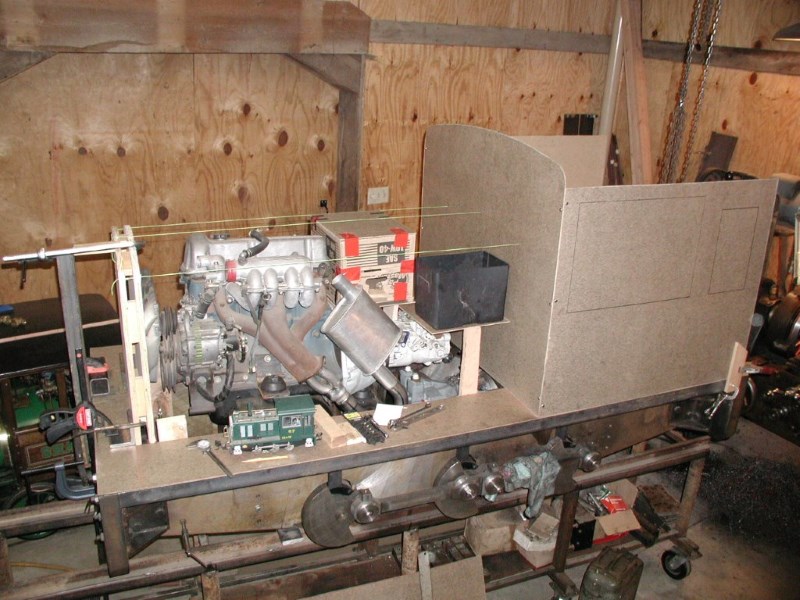

Time to fit up the engine and mounts.

Wood and cardboard were used to mock-up the hood and cab to make sure everything was going to fit.

The first "run" was with the locomotive was with it still on the test stand. Blocks were put the frame to lift the wheels a little off of the rails so they could freely turn. The system worked great. Sometimes success deserves beer.

First test run on the rail for #57. After testing a tweaking on the stand the chassis was lowered onto the rails for it first true tests. It ran better, and faster, than expected. There's a High-Low switch as we found the "High" was much too fast for our little railroad. The cab was a little breezy though.

Testing complete the locomotive was torn apart and the painting began.

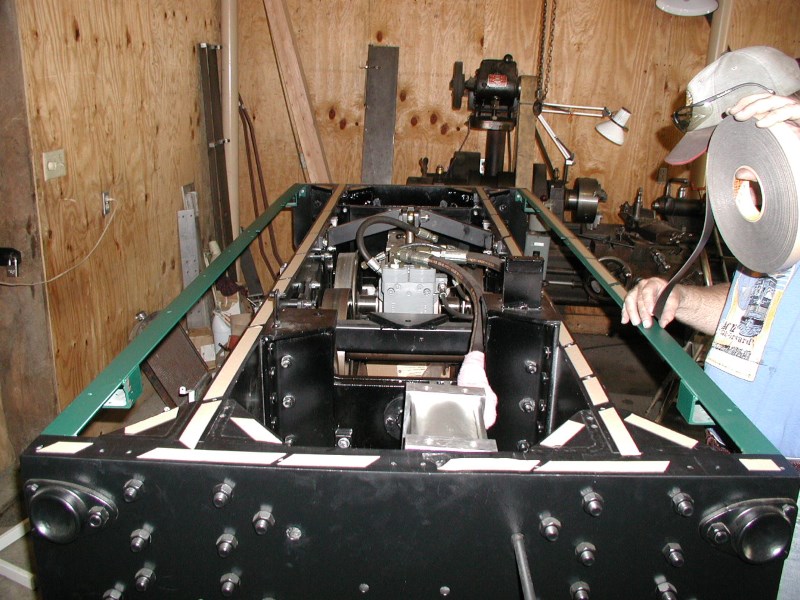

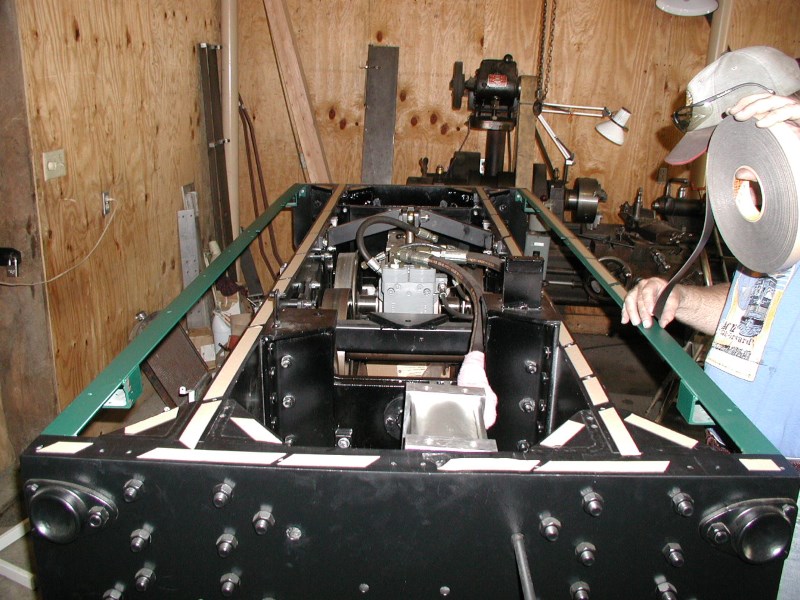

Installing the hydraulics into the painted chassis.

Anti-vibration tape was applied before the deck was put down. Not using it would have been cheaper, but, again, it would have made for a cheaper locomotive, not a quality one.

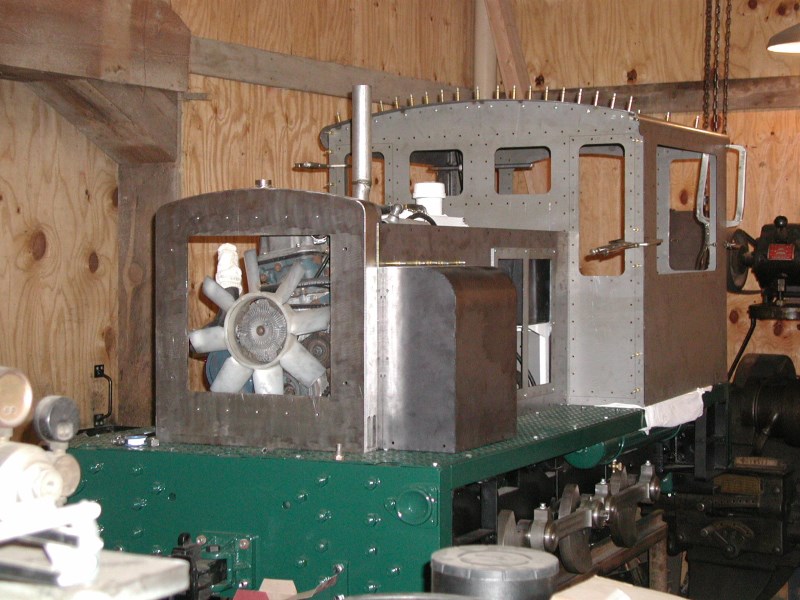

With the drive system & chassis working, the erecting of the hood and cab began.

Engine mounted onto the painted chassis.

Cleco's were used to fit and hold the sheet metal for riveting. There are NO FAKE RIVETS anywhere on the locomotive. Even the frame was hot riveted together.

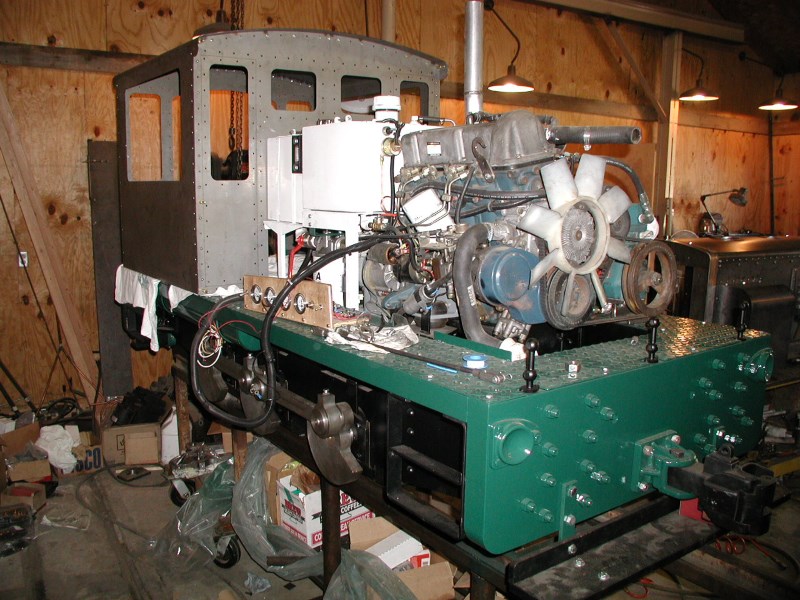

Cab on working on the dashboard electronics and controls.

Final Installation of the dashboard and controls. The Throttle, brake valves and the Displacement (Forward-Reverse) lever are positioned identical to our steam locomotives so that engineers trained on the #57 can get into the cab of a steam locomotive and know instantly what's-what and how to control the locomotive. This is also a safety matter as the brake valves on all engines, steam or diesel, are identical for fast action by the engineer without having to stop and figure out which is the train brake and which is the locomotive brake.

Artisan Chris Allen volunteered to hand paint the lettering onto the cab. From 2007 to 2015 that lettering is still on the cab. Vinyl lettering would not have held up that well.

A view of the access doors open for regular maintenance. For more extensive work the whole hood can easily be removed.

The locomotive is overpowered for passenger service as it will pull every car on the railroad with the diesel engine in idle.